Welding and automation for production excellence

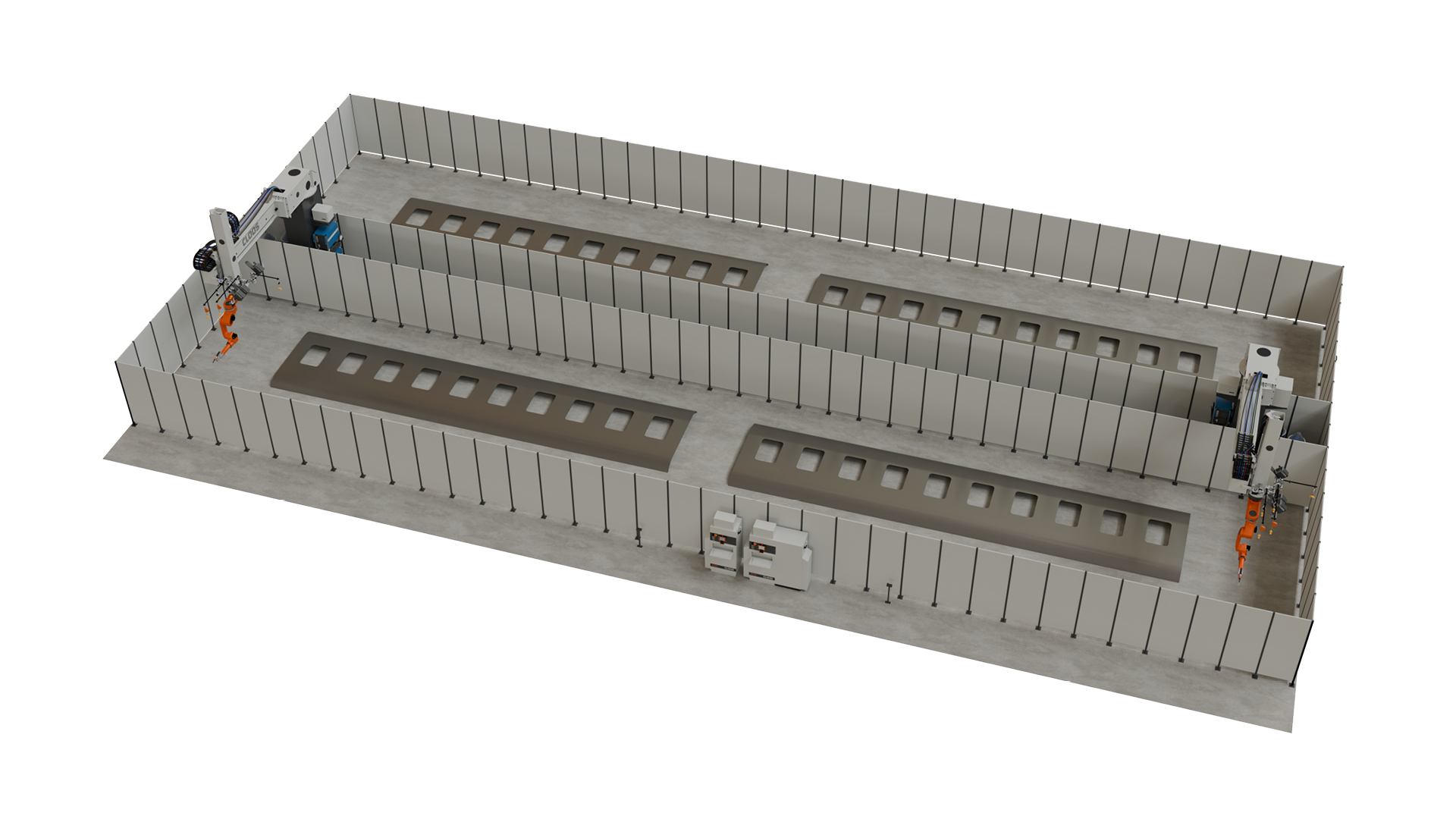

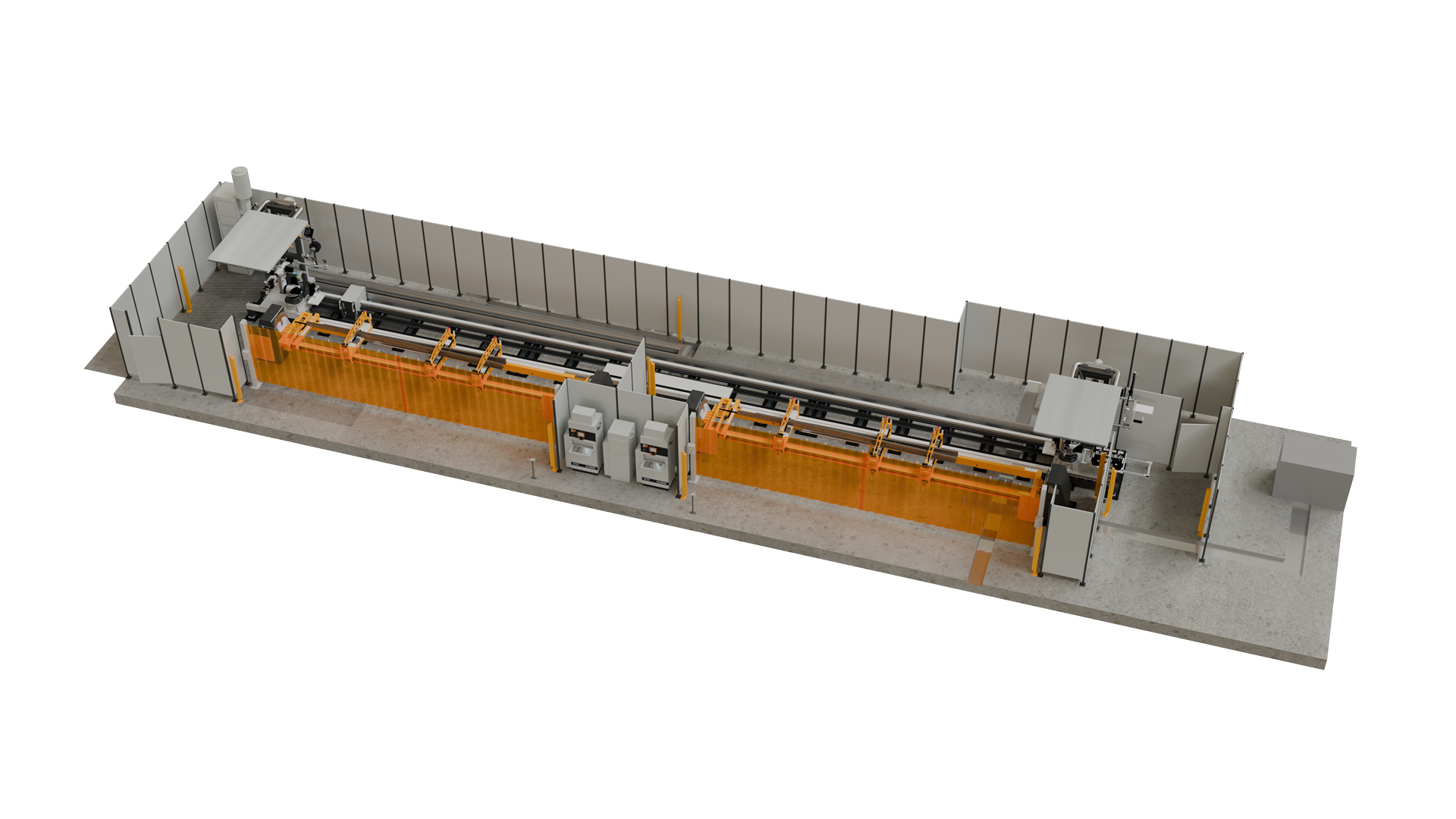

The requirements in railway vehicle construction are constantly increasing. Factors such as higher safety standards, increased efficiency and growing cost pressure are presenting manufacturers with new challenges. In this context, the joining process is becoming increasingly important. With our high level of innovation and many years of experience, CLOOS develops individual welding solutions that are perfectly tailored to your needs.

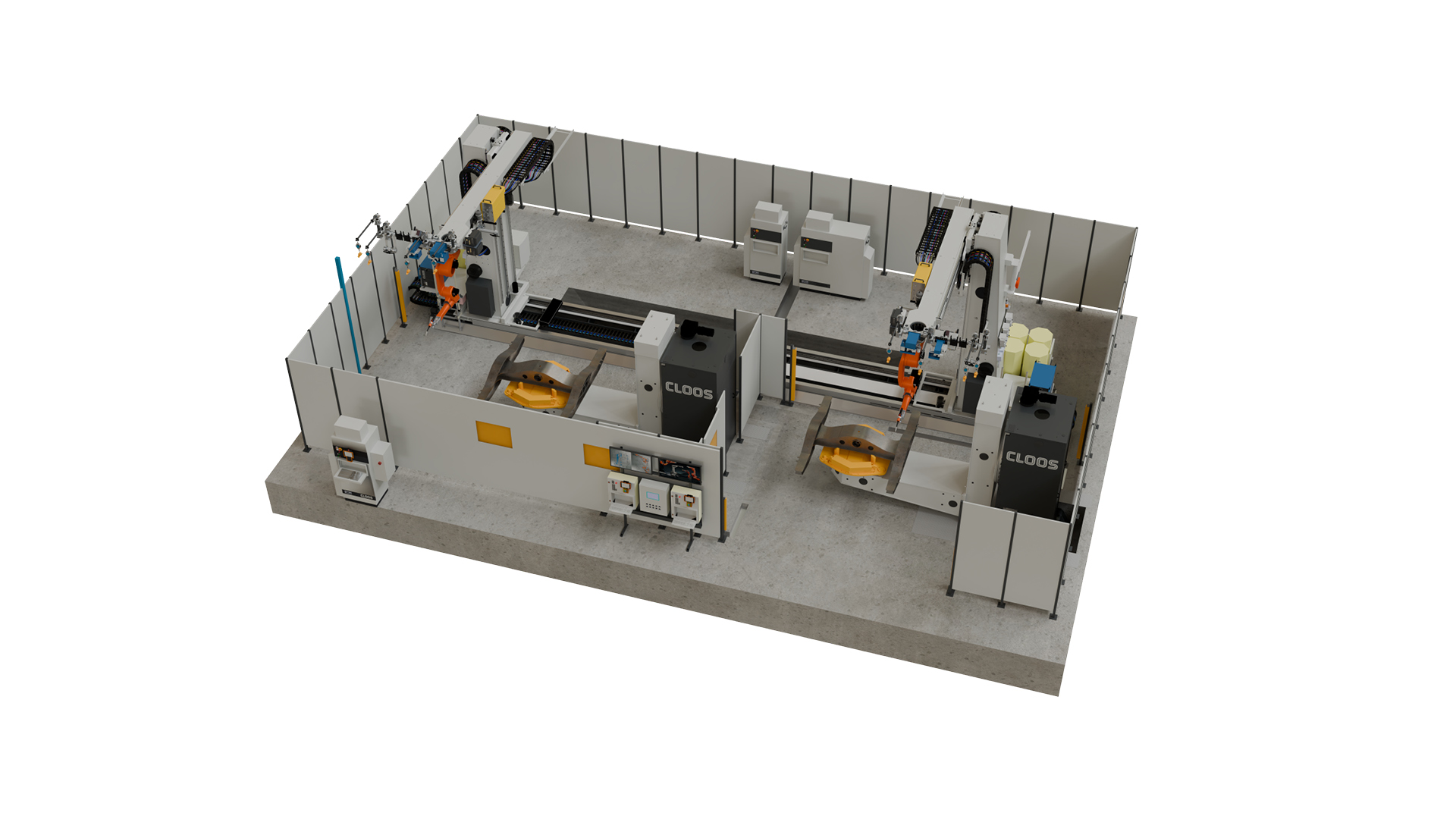

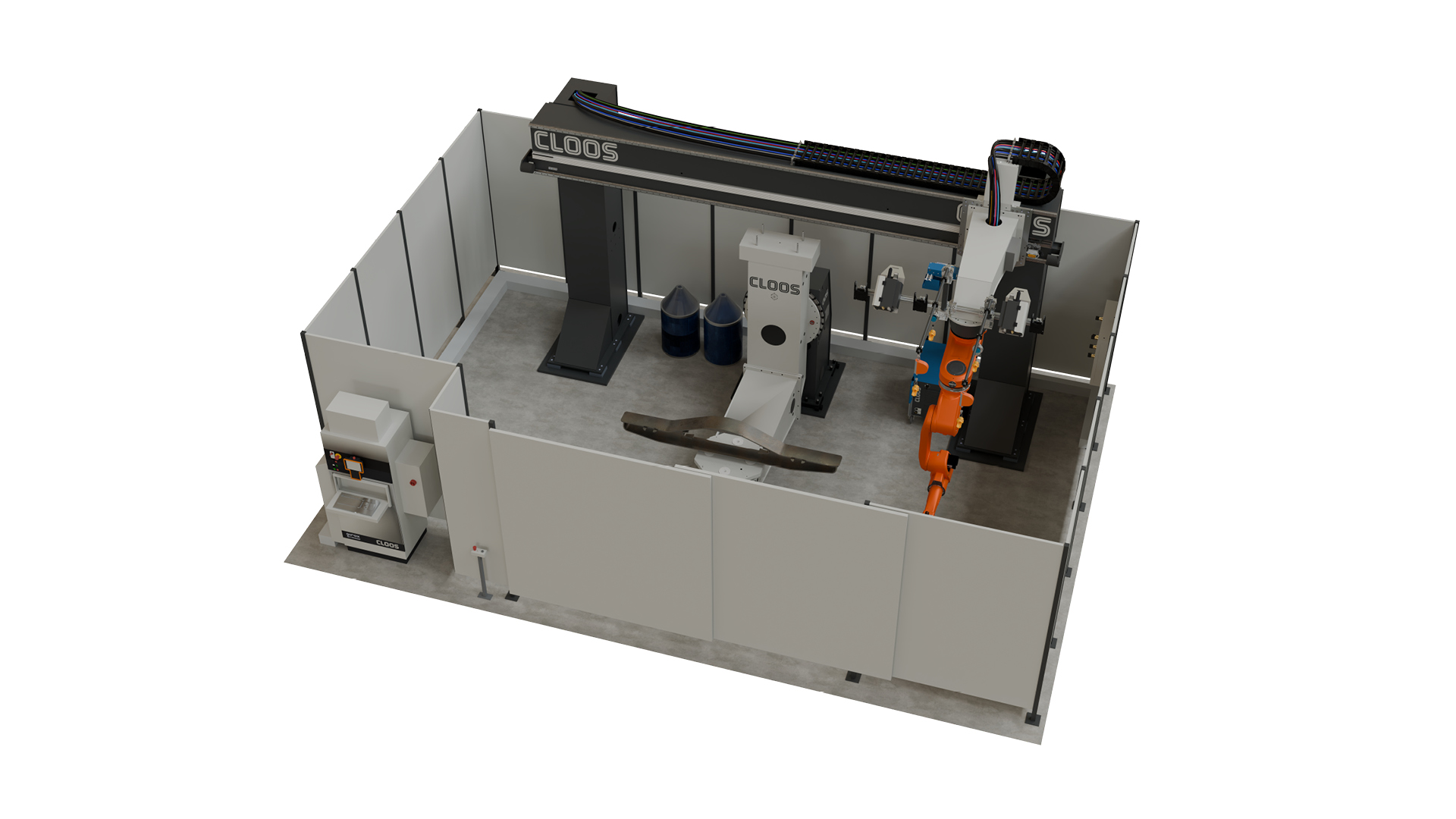

Our customers benefit from state-of-the-art welding technologies that stand for precision, reliability and durability. Thanks to our automated welding systems, you can increase production quality, reduce production times and cut operating costs at the same time.

Companies from a wide range of industries have been relying on CLOOS for decades. Our expertise in railway vehicle construction enables us to offer you customised solutions that help you to successfully master the growing requirements. Rely on CLOOS - for innovative, efficient and future-proof welding solutions.